Mud Brown Section

Emergence is becoming visible when something or an object is initially hidden or concealed from view. An example of this is how light emerges from electricity. So I will be making a light product that will also draw inspiration from the term disruptive innovation.

The following information is from this website https://claytonchristensen.com/key-concepts/

Disruptive innovation, a term of art coined by Clayton Christensen, describes a process by which a product or service takes root initially in simple applications at the bottom of a market and then relentlessly moves up market, eventually displacing established competitors.

As companies tend to innovate faster than their customers’ needs evolve, most organizations eventually end up producing products or services that are actually too sophisticated, too expensive, and too complicated for many customers in their market.

Companies pursue these “sustaining innovations” at the higher tiers of their markets because this is what has historically helped them succeed: by charging the highest prices to their most demanding and sophisticated customers at the top of the market, companies will achieve the greatest profitability.

However, by doing so, companies unwittingly open the door to “disruptive innovations” at the bottom of the market. An innovation that is disruptive allows a whole new population of consumers at the bottom of a market access to a product or service that was historically only accessible to consumers with a lot of money or a lot of skill.

Characteristics of disruptive businesses, at least in their initial stages, can include: lower gross margins, smaller target markets, and simpler products and services that may not appear as attractive as existing solutions when compared against traditional performance metrics. Because these lower tiers of the market offer lower gross margins, they are unattractive to other firms moving upward in the market, creating space at the bottom of the market for new disruptive competitors to emerge.

Yet the term 'disruptive innovation' is used to often. Because of this it creates a mess in the market where what is actually innovative and what is pretending to be innovative get muddle up together creating a mess.

Anyway the light product I will be making will attempt to display the mess of disruptive innovation by actually trying to be innovative but also being a mess. Yet the mess is not really a mess its a form of controlled disorder.

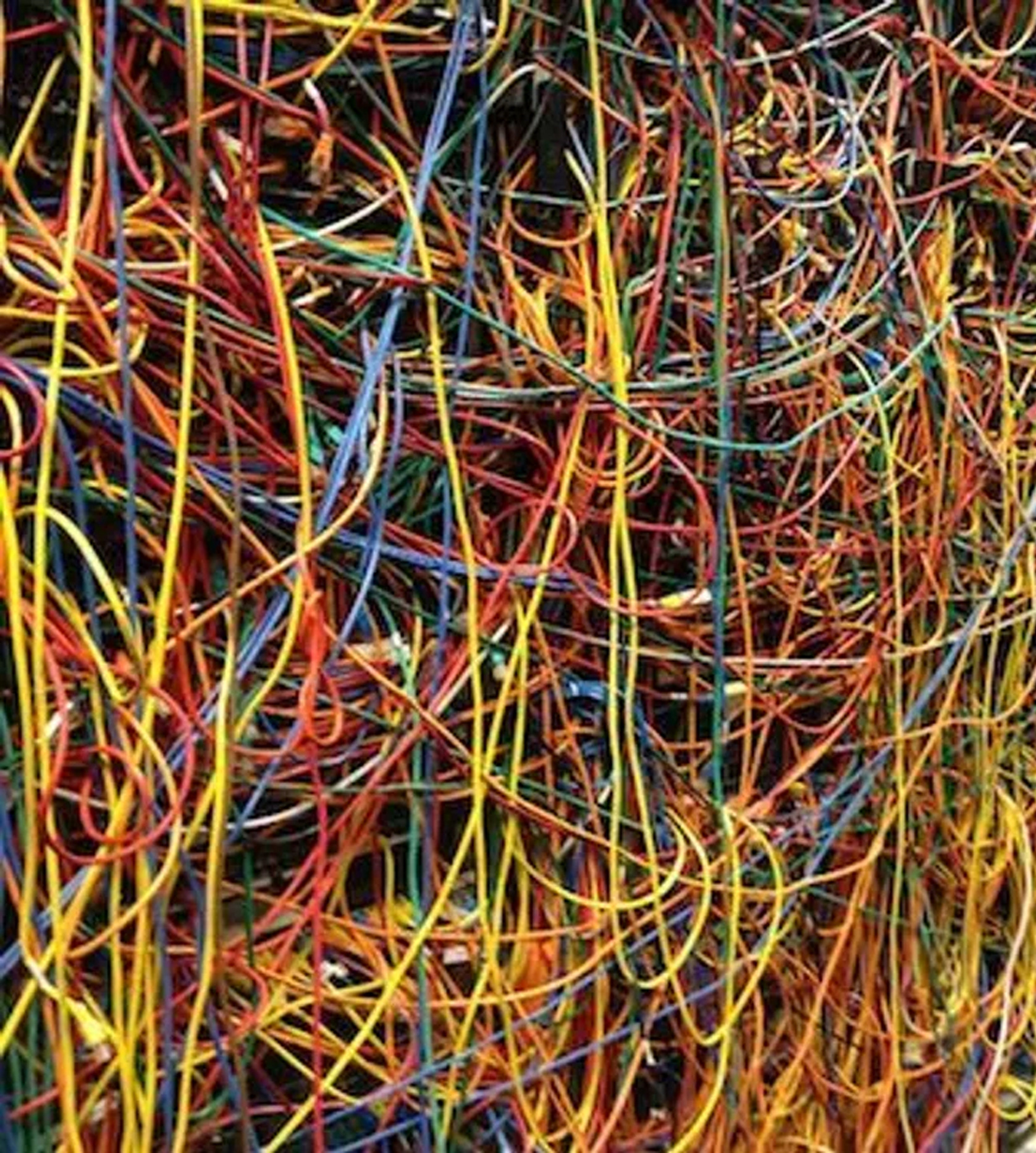

Since the light will have to come from electricity which flows across wired cables, the light will be made mostly out of cable. Eliminating any additional materials that are primarily used for aesthetic reasons only.

Since it can take a considerate amount of time for a product to reach the top of the market I made the choice of using a clock as initial inspiration. an average wall clock is 30cm in diameter. so the plan was is to make the light the same size as a clock. Also since there are twelve number this would effect the thickness of the light. Since I would be using cables I would need a material that is easy to use and manipulate so that when the cable is wrap around it wouldn't be difficult to separate the two without damaging the cable. I used form board because of these reasons. The form board is 6mm thick so times that by 12 would make the overall thickness/width of the light 72mm.

=

2nd model

I decided that I was going to make a second model. Yet it wouldn't be out of cable, instead i would use something that conducts electricity but not initially known for doing so. while researching such materials i came across conductive pla. Therefore the 2nd model would be a panel light again but 3d printed using this type of pla. this will be hit or miss if I'm being honest. although there are examples of the material being able to conduct electricity, there are examples of it not. Therefore it will be trial and error. that being said 500g of this type of pla is £60 with vat and delivery so i wont be making multiple models instead I will do initial testing with a cut off piece of the pla that isn't printed first of all.

The video above shows practice prints used to find a good enough fit for the plug and battery pack. it also shows how the remote for leds stop working. so unfortunately the lights in the panel will flicker between different colours.

The video above is just a test. it was done just to find out how much current can pass through the pla. the video shows that it is conductive enough yet the current is not strong. therefore this could be a problem when it comes to printing off the plug part of the panel. since it may not be able to pass enough current through it.

The video above is showing another test. Which was making sure the plug part was shaped properly before printing it with the conductive pla.

as it tuned out the plug part wasn't able to conduct enough electricity through it. Although this was a shame i decided that as long as i could prove that the material is conductive enough for leds then it would be some form of success.

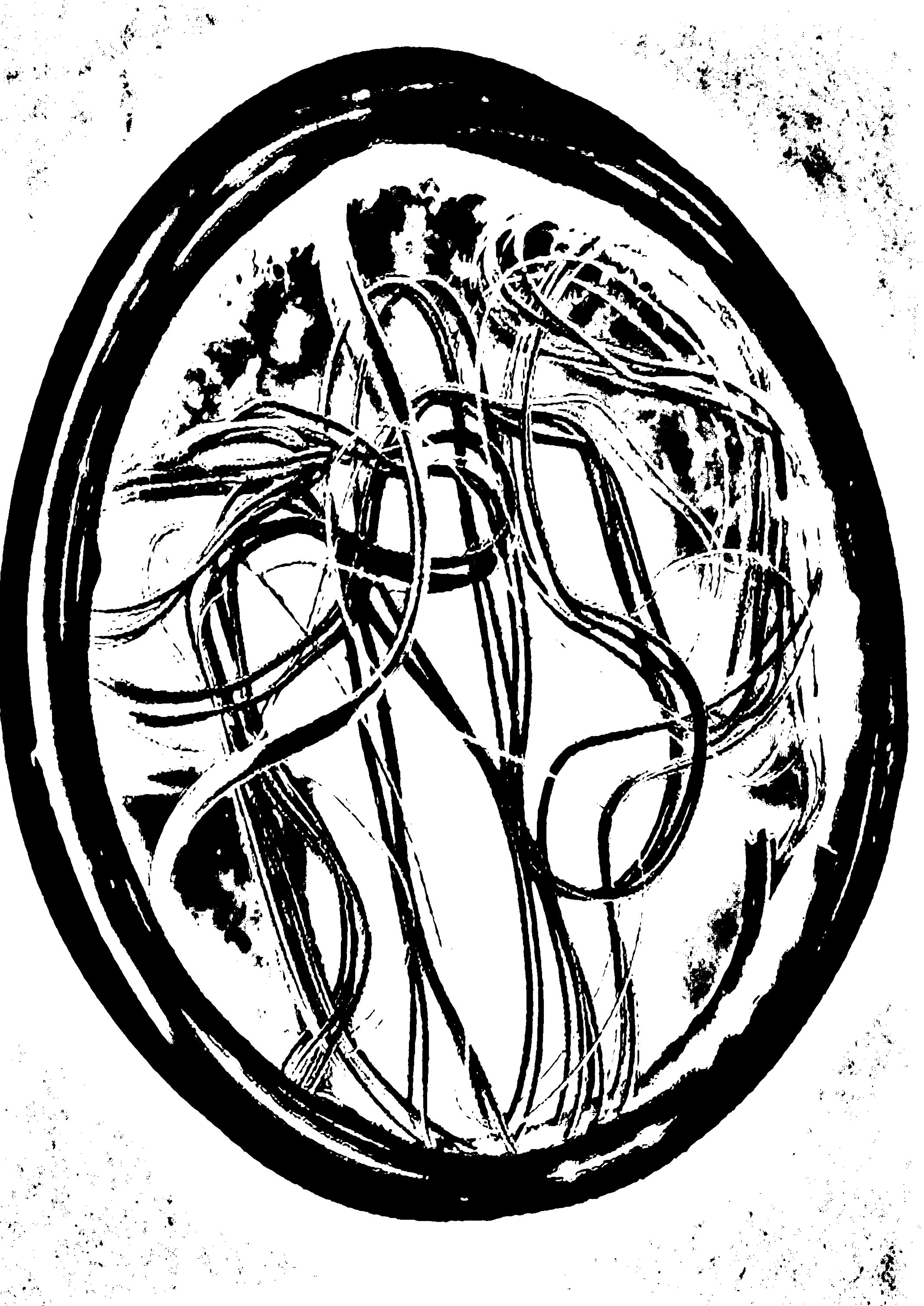

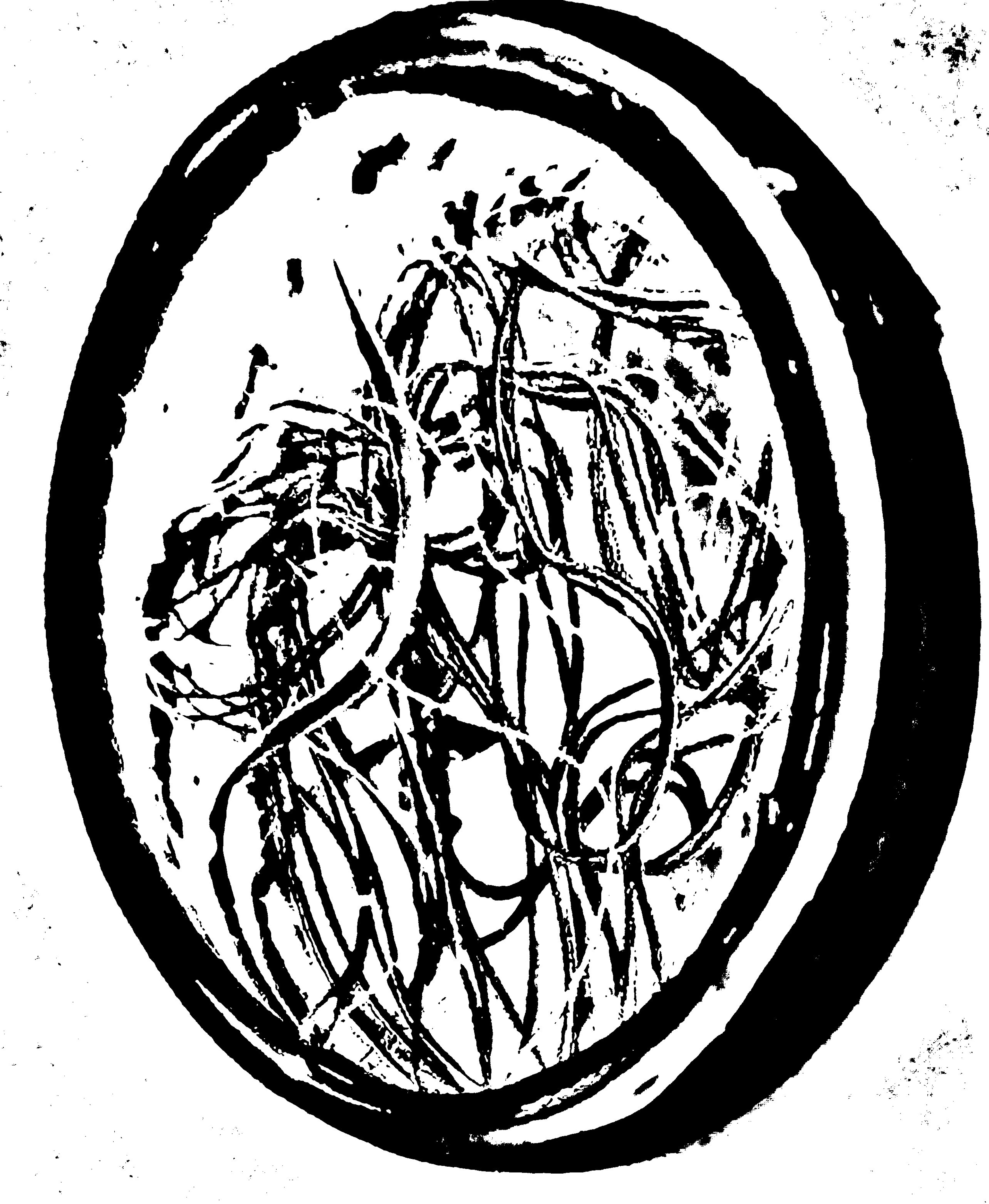

The mirror in both models is there to reflect the term disruptive innovation by displaying the entanglement in front of it, which is the mess of actually determining what is disruptive innovation.